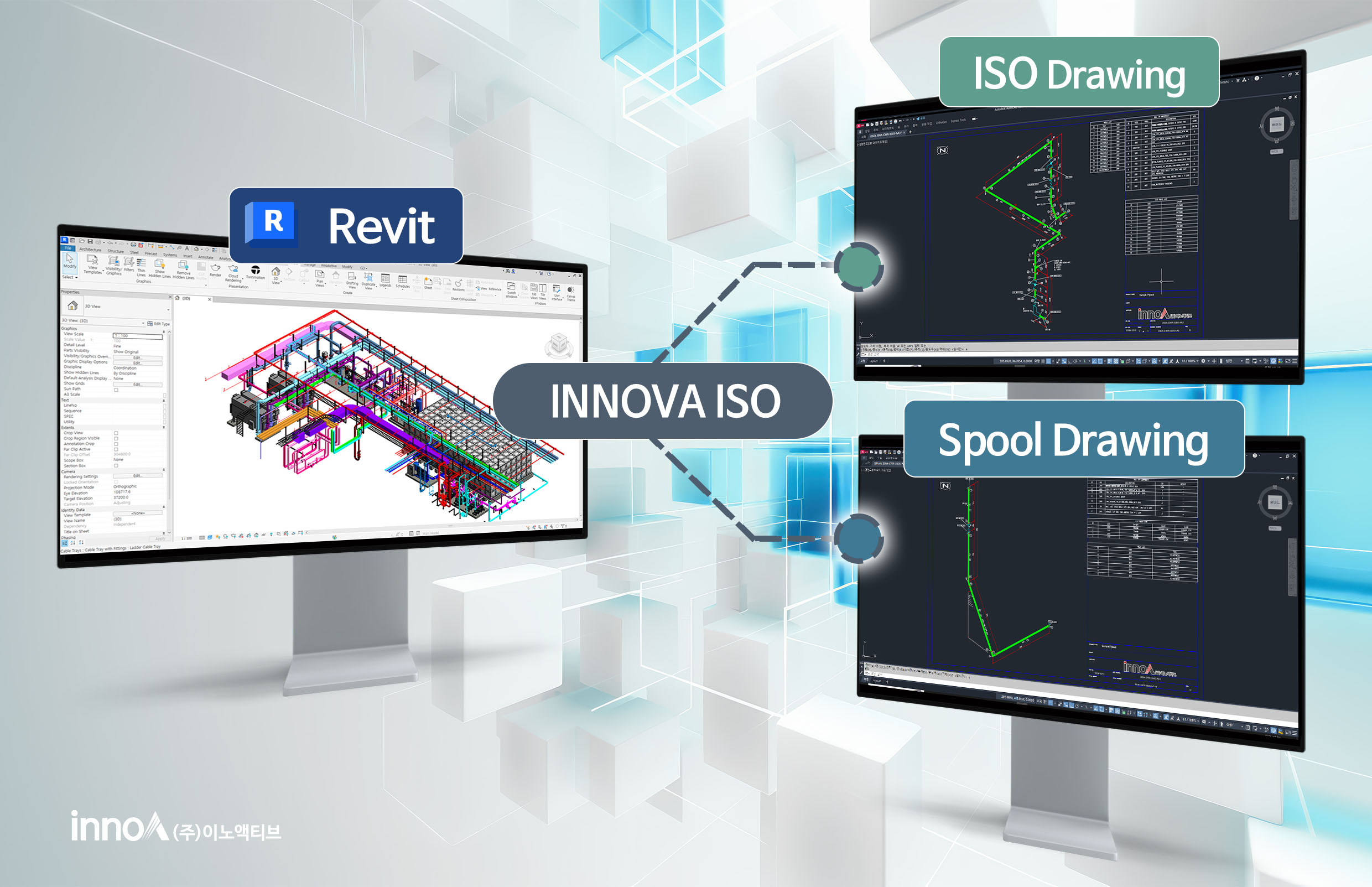

INNOVA ISO, which presents new possibilities, is a conversion solution that innovates ISO and Spool Design work.

Original Model

Utilize the original model

Data Convergence

Multi-model data conversion

Attribute Sync

Supplement ISO property information

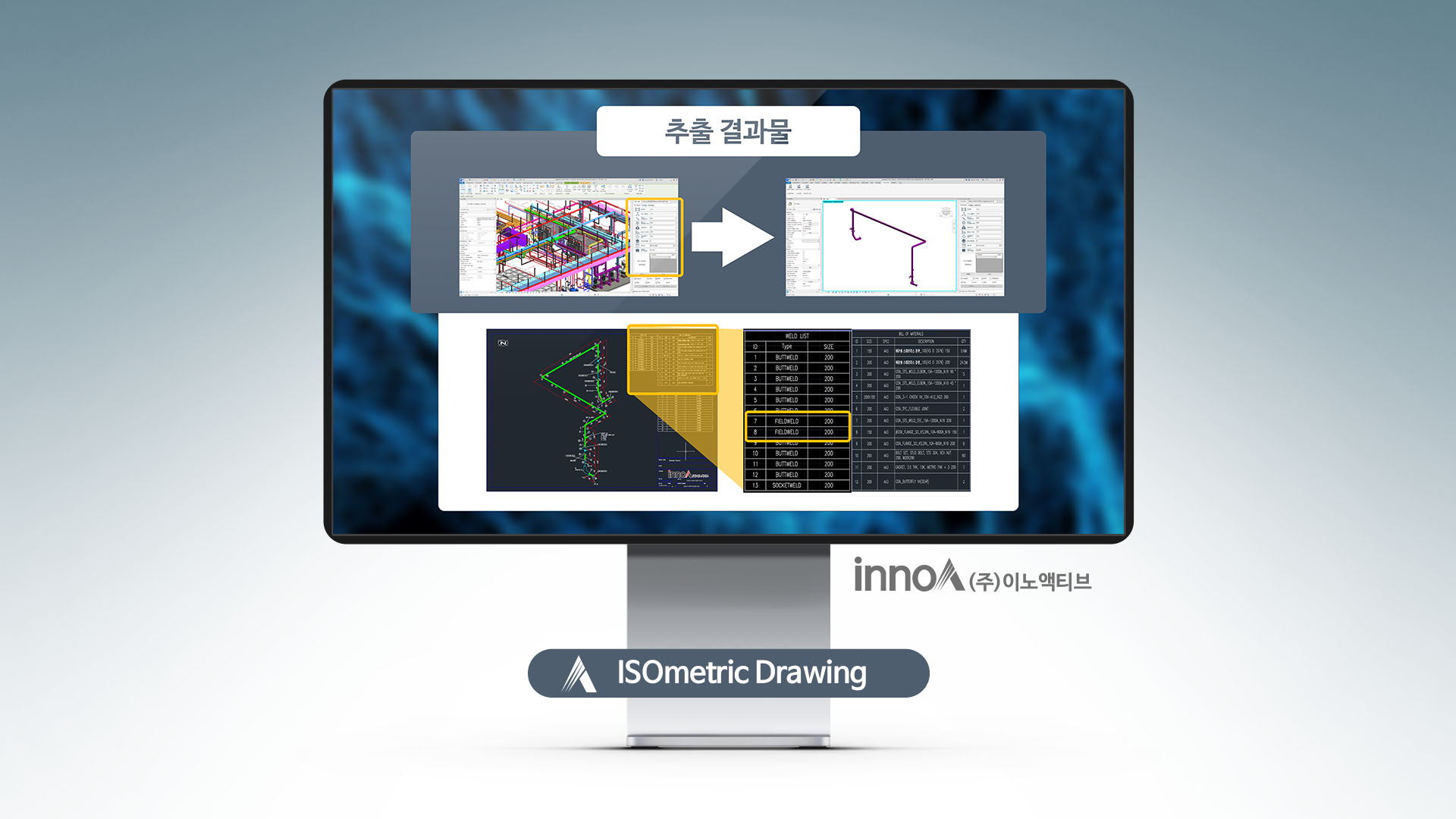

ISOMETRIC Drawing Generation

Securing productivity and saving resources by creating drawings needed for work

INNOVA ISO streamlines business processes to generate isometric drawings.

Stability

Automatic attribute information mapping

Efficiency

Increased convenience for model review through Data Sync

Productivity

Reduction in manual tasks and business processes

Scalability

Extraction of drawings suitable for the business

Using trained data to generate ISO drawings in Revit with one-stop

Supports Autodesk Inventor, Dassault Systemes CATIA, SolidWorks, PTC Creo, and more

INNOVA ISO Module

INNOVA ISO Module:

Revit to ISO

INNOVA ISO Module: Maker to ISO

The INNOVA ISO product line consists of two modules that generate ISO drawings in Autodesk's AEC Collection, Revit, and in PDMC, Inventor. "Revit to ISO" is a solution that generates ISO drawings by converting Revit's model information into a database, while "Maker to ISO" is a server module that generates ISO drawings based on the PCF of Inventor models. Both modules provide consistent, high-quality ISO drawings.

Revit to ISO

INNOVA ISO consists of two modules: one for extracting ISOs from Revit, a product included in Autodesk's AEC Collection, and another for generating ISOs in Inventor, included in PDMC. "Revit to ISO" is a solution that generates ISOs by converting Revit's model information into a database.

INNOVA ISO

One-Stop Revit ISO Generation Solution

INNOVA ISODrawing Automation

Automated creation of ISO and SPOOL drawings for piping design, fabrication, and installation

Process Optimazation

Easy customization and process simplification

High Quality Drawing

Consistent, high-quality drawing generation

Human Error

Post-Correction Work

Low Productivity

Preconditions Required

Preparatory Work Required

Repetitive Process Occurrences

INNOVA ISO

INNOVA ISO enhances a company's competitiveness by providing high efficiency, quality, and productivity in ISO design.

Minimized User Intervention

Increases work efficiency, reduces errors, and allows focus on creative tasks.

No Preconditions

No need for prior settings, enabling quick start of work.

No Pre- and Post-Processing Required

Simplifies processes, saves time and resources, and ensures data consistency.

Elimination of Repetitive Processes

Maximizes work efficiency, improves productivity, and shortens project time.

Automatic Error Handling

Instant error correction, maintains quality of output, and focuses on key tasks.

Key Advantages of INNOVA ISO

Enhance your work efficiency and quality by adopting INNOVA ISO.

ISO generation using information that can differentiate systems

Ability to modify models by checking the number of elements in a line number: Model highlighting / Correcting erroneous models before ISO generation

Settings values generated in existing projects can be mapped to new projects and applied immediately without reconfiguration